Hazira is barely a 20 minutes drive from Surat. But as the car leaves Surat behind, the landscape changes. On both sides of the highway are industrial estates that include some of the best known companies listed in the Indian bourses.

Half-an-hour later, the car comes to a halt at the huge gates of one of our biggest private sector conglomerates: Larsen & Toubro. The company’s close to 850 acre premises is spread on both sides of the highway. Within the premises is the manufacturing facility of a product that the Indian Army’s Gunners are awaiting with bated breath: the K9 VAJRA-T 155mm/ 52 Cal Tracked Self Propelled Gun.

Half-an-hour later, the car comes to a halt at the huge gates of one of our biggest private sector conglomerates: Larsen & Toubro. The company’s close to 850 acre premises is spread on both sides of the highway. Within the premises is the manufacturing facility of a product that the Indian Army’s Gunners are awaiting with bated breath: the K9 VAJRA-T 155mm/ 52 Cal Tracked Self Propelled Gun.

The Indian Army had last imported the Bofors FH 77B O2 155 mm/ 39 Cal Self Propelled Towed Gun in the late 1980s. However, the Bofors scandal effectively put paid to all attempts at Artillery modernization, thereafter.

Now, after three decades of the scandal, India has opted for two contracts to meet the immediate requirement. These include contract for 145 of 155mm/ 39 Cal Ultra-Light Howitzers manufactured by BAE Systems. These are meant for mountain divisions of the Army. The other contract entered into is for a 100 of K9 VAJRAs to be manufactured by L&T. The K9 VAJRA self-propelled tracked system, is suitable for mechanised formations that operate best in deserts.

L&T’s partner in the manufacture of the guns is Hanwha Land Systems, part of Hanwha Group, South Korea’s largest defence sector conglomerate. Hanwha acquired Samsung-Techwin as a part of consolidation in the Korean Defence Industry to emerge as the largest producer of tracked self-propelled guns globally, with over a 1000 pieces in service with various armies, globally.

The K9 VAJRA-T is based on the design of K9 Thunder which is in service with the Korean and a few other armies. The gun system has been modified to suit Indian requirements. It is planned to have greater than 50% indigenous content.

L&T has concurrently built a whole new manufacturing complex at its Hazira premises for the manufacture of these guns inclusive of state-of-the-art test tracks to qualify mobility of every gun system produced here. The Armoured Systems Complex is a huge workshop that will house the entire assembly line starting from manufacture of various sub-systems and systems of the gun. Currently the super-structure is in place with the final stages of integration of systems are being undertaken here. The machinery and wherewithal for the preceding stages in manufacture are in the process of being moved in to the Armoured Systems Complex as also feeder shops within the campus.

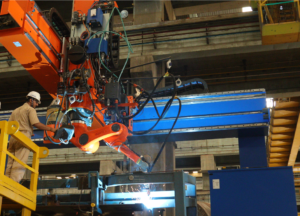

Activities on the manufacturing line begin with receiving of raw material and stores from both domestic and international sources. Post receipt, the material is processed for hull and turret structural fabrication by cutting and machining. The methods used in cutting include water jet, laser and plasma cutting.

The material, thereafter, is moved to the Heavy Fabrication Shop. An enormous amount of welding is undertaken in the shop by using both manual, semi-automated, automated and robotic means while yielding distorsion-free structures. Interestingly, the highly skilled welders & fabricators at L&T spend most of their working lives with the company. The accuracy required in welding of special alloy steels for armour plating calls for exceptional skill levels that are honed over the years. L&T’s welders and progressively improve their competence levels and are an important multi-skilled resource for the company.

The material, thereafter, is moved to the Heavy Fabrication Shop. An enormous amount of welding is undertaken in the shop by using both manual, semi-automated, automated and robotic means while yielding distorsion-free structures. Interestingly, the highly skilled welders & fabricators at L&T spend most of their working lives with the company. The accuracy required in welding of special alloy steels for armour plating calls for exceptional skill levels that are honed over the years. L&T’s welders and progressively improve their competence levels and are an important multi-skilled resource for the company.

The joining of the lower hull and the upper hull, two major parts of the gun system’s hull, is undertaken here. Similarly, the assembly of the fabricated turret is undertaken in the adjoining shop.

Post the welding and fabrication, examination and inspection needs to be diligently carried out. Modern methods like Magnetic Particle Testing and Radio Graphic Testing are employed. Qualification inspections are carried out by in-house dedicated specialist teams.

The next steps are being undertaken in the newly erected Armoured System Complex. The hulls and turrets are machined using CNC Plano Miller in the high-tech machining facility followed by shot blasting and painting. Concurrently, the processes of matching and integration of sub-systems is completed here. Approximately, 5000 parts and assemblies are to be manufactured and uniquely integrated to build the K9 VAJRA Gun System. Among the major tasks at this stage are aligning the barrel with the sighting system of the guns, an activity crucial for accuracy of the entire gun system.

It’s at this stage that the gun is prepared for final painting by short blasting followed by the user requirement of camouflage painting to ensure that once fielded in operational environment the gun merges with its surroundings to make detection by the enemy, difficult.

Three guns have rolled out of this complex and have successfully fired Indian ammunition in Mahajan Field Firing Ranges. The next two pieces are in the final stages of testing. A few more are undergoing integration.

L&T’s Armoured Systems Complex is in effect perhaps amongst the largest such integrated manufacturing line under one roof for manufacture of these cutting-edge weapon systems. When fully functional, every activity to be undertaken in the manufacture of the equipment will be under one roof. It caters for dust free enclosures, temperature controlled areas for meeting the full range of conditions required for manufacture and assembly of sub-systems. Even more interesting is the innovation at work in building in-house a range of Jigs, Fixtures and Tooling to ensure operational efficiency.

L&T’s Armoured Systems Complex is in effect perhaps amongst the largest such integrated manufacturing line under one roof for manufacture of these cutting-edge weapon systems. When fully functional, every activity to be undertaken in the manufacture of the equipment will be under one roof. It caters for dust free enclosures, temperature controlled areas for meeting the full range of conditions required for manufacture and assembly of sub-systems. Even more interesting is the innovation at work in building in-house a range of Jigs, Fixtures and Tooling to ensure operational efficiency.

As L&T is committed to meet its timelines and a 100 guns will have traversed through the length of the Armoured Systems Complex, ready for operational deployment by November, 2020.

The 48 ton K9 VAZRA-T, once it leaves the Armoured Systems Complex is a formidable weapon system. Driven by a 1000 Horsepower engine, it can range over 38-43 km with great precision. With speed being essential to mechanized operations, the 48 ton gun can drive at a max speed of 60 kmph. It can ford up to a depth of 1.5 meters and go across a trench 2.8 meters wide.

The gun fires in burst fire mode of three rounds in less than 30 seconds. At intense rates of fire. 15 rounds can be fired in less than three minutes. The sustained rate of fire is a round per minute for an hour. The system has a direct fire capability and can effectively engage a tank at 1 km. The Gun system is capable of MRSI (Multiple Round Simultaneous Impact) and can land three rounds on a target simultaneously. The sighting system caters for all possible conditions. Its automated loading system loads the round. The elevation/ depression and traverse of the barrel for ranging on to the target is also automated.

The crew strength of five is much lesser than the towed system that requires eight plus the driver of the towing vehicle. The K9 driver is provided with a night vision system enabling him to drive in pitch darkness making the weapon system capable of operating round the clock. Crew comfort in deserts is addressed by an air cooled overall / vest linked to an air conditioning system. Crew survival systems for nuclear, biological and chemical attacks are also integrated.

The K9 is undoubtedly the artillery equipment that our mechanised formations need. The Armoured Systems Workshop is also surely one of the best manufacturing lines for guns & armoured systems. L&T has invested heavily on the project. Indian mechanised formations require a lot more of these guns and associated armoured platforms. A repeat order surely could follow if the pace of military modernisation is to be maintained and Make-in-India promoted actively. With a world class product, L&T could find an export market if it can be cost competitive; something that is quite feasible given the advantage of higher scales of production. Such an endeavor would definitely provide a surge to the Make in India concept.

(The writer was hosted by L&T at their premises in Hazira, Gujrat)

Brig SK Chatterji (Retd)